Volkswagen Group of America, Inc., Fairfax County

A Welcoming Business Climate for Manufacturers

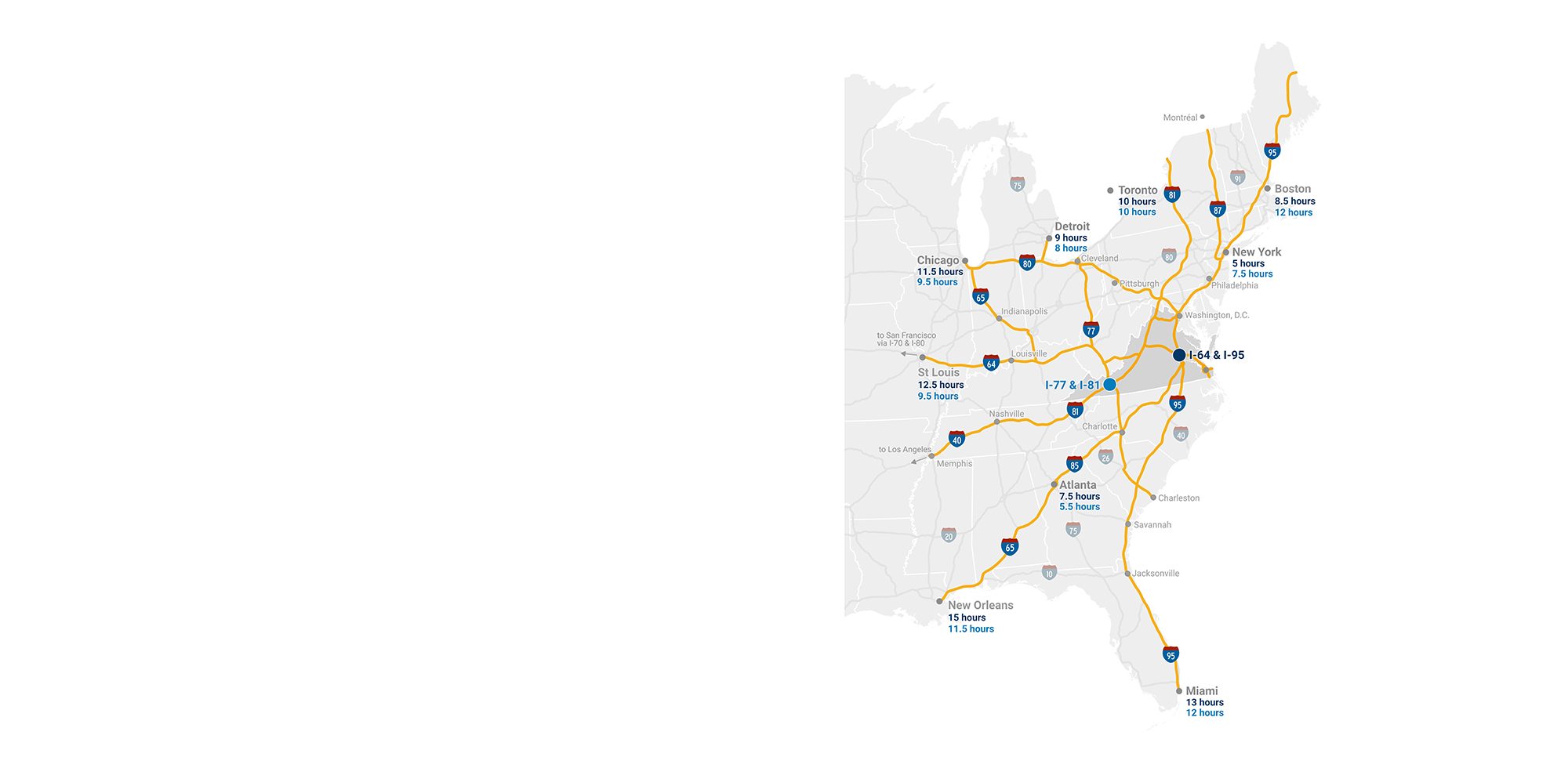

- Virginia is the northernmost right-to-work state along the I-95 Corridor.

- Virginia has had a stable 6% corporate income tax rate, one of the lowest in the nation, since 1972.

- Sound economic policy and prudent financial management has earned Virginia a AAA credit rating since 1938 — longer than any other state.

- Virginia has a low natural disaster risk and is tied No. 4 among ‘States Most Prepared for a Disaster,’ according to 24/7 Wall Street.

- With 450+ fully characterized development sites of 25 acres or larger, dozens of certified sites, and a growing inventory of spec buildings and virtual buildings, Virginia is constantly working to improve its portfolio of real estate options for manufacturing companies.