The I81-177 Crossroads: A Leader in Advanced Materials & Composites

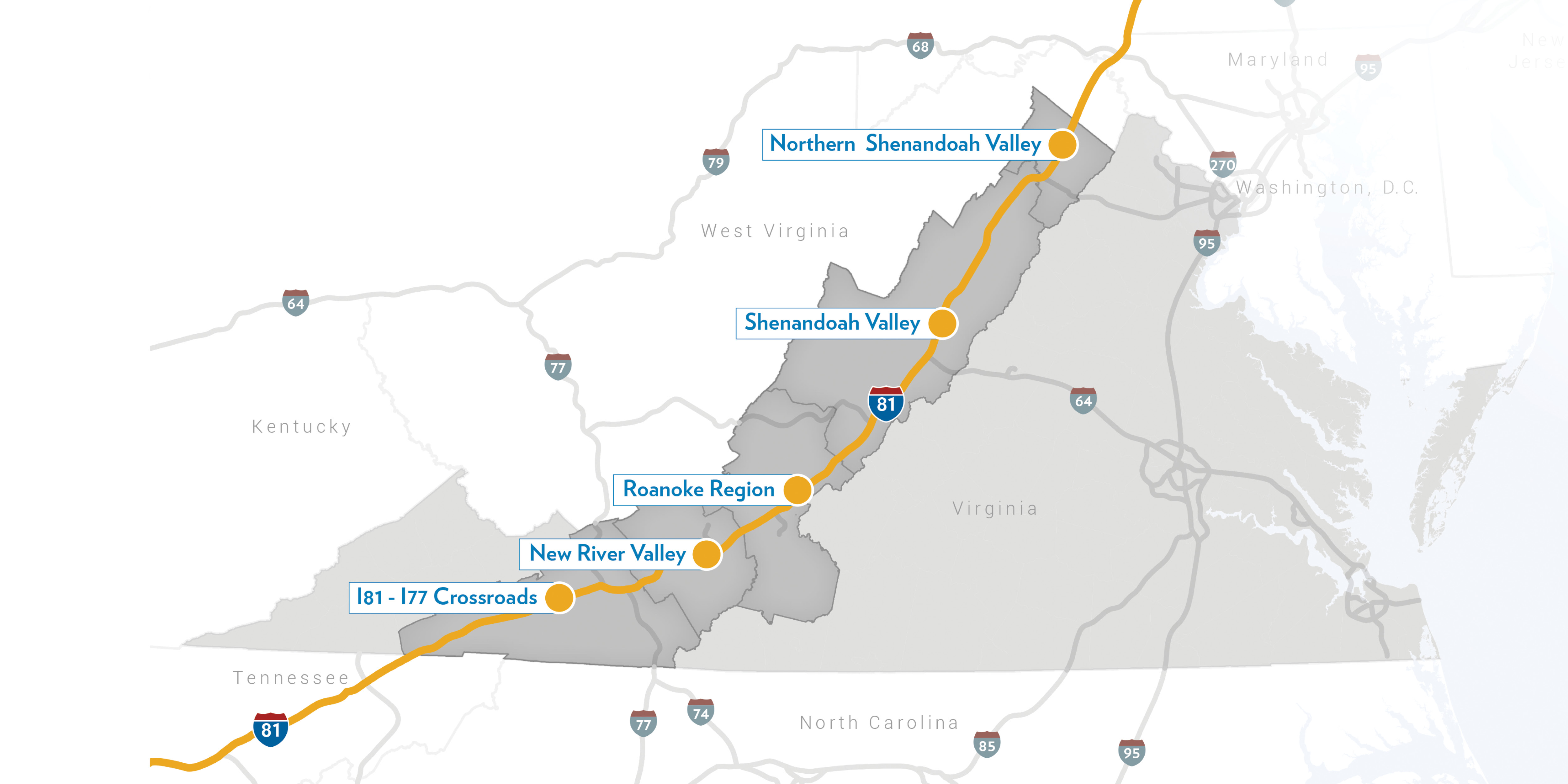

While many drivers along the Interstate 81 Corridor focus on the beauty of the surrounding mountains, I-81 is the backbone that connects a thriving manufacturing industry. Unlike many interstate systems, I-81 circumvents major metro areas to connect smaller and mid-size cities. But throughout those cities and scenic stretches of Blue Ridge beauty are manufacturing operations that support one another and buyers around the world. A journey along I-81 reveals just how impressive a package Western Virginia offers manufacturers in almost any industry looking for a supportive region in which to expand.

We begin our journey where I-81 enters Virginia at its southern border with Tennessee, near Bristol. Composed of six counties (Bland, Carroll, Grayson, Smyth, Washington and Wythe) and two cities (Bristol and Galax) with a total population of nearly 200,000, much of the area lies in picturesque valleys bordered by the Blue Ridge and Allegheny mountain ranges. Outdoor activities are abundant in the region, which is home to portions of Jefferson National Forest and the Appalachian Trail. The Virginia Creeper Trail, a 34-mile rail-trail running between Abingdon and Whitetop, has been described as the best mountain-bike trail in the East. Designated the “Birthplace of Country Music,” musical heritage is vitally important. Bristol’s Birthplace of Country Music Museum is a stop on the “Crooked Road: Virginia’s Heritage Music Trail,” and more than 40,000 visitors annually flock to the internationally known Old Fiddler’s Convention in Galax.

The region is named after the point where interstates 81 and 77 merge in Wythe County, an intersection positioned to unlock markets to the south, including Charlotte and Atlanta via I-77 and Memphis and Nashville via I-81 and industrial markets in the Midwest via I-77. The Crossroads’ prime logistics infrastructure via road and rail has allowed a diverse manufacturing base to develop and thrive.

The region has a long history in manufacturing and advanced materials. In 1924, Strongwell Corp. established its first plant in Bristol. Back then it was a furniture factory, but the company got a taste for advanced materials manufacturing during World War II when it produced carbon parts for weaponry. During the 1940s, the company began its work in reinforced plastics. Today, Strongwell is an industry leader in pultruded fiberglass products used in an incredible range of applications.

The company operates two facilities in Virginia. At 398,000 square feet, the Bristol location is its largest manufacturing plant, with a second one located in nearby Washington County.

The Bristol headquarters alone houses more than 35 pultrusion machines and a 10,000-square-foot laboratory capable of testing new fiberglass reinforced plastics to stringent ASTM standards. To fuel its operations, the company seeks to support and draw from the local workforce by sponsoring area robotics competitions and participating in career exploration events with local middle school students.

In addition to composites manufacturers, plastics processors also operate in the region. With an advantageous location in Wythe County’s Progress Park, a 1,200-acre certified site with the high-capacity infrastructure for advanced manufacturing projects, Amcor Rigid Plastics serves the adjacent 1,000,000-square-foot PepsiCo Gatorade facility and regional food and beverage manufacturers. The facility is one of 195 facilities that the global packaging leader operates worldwide.

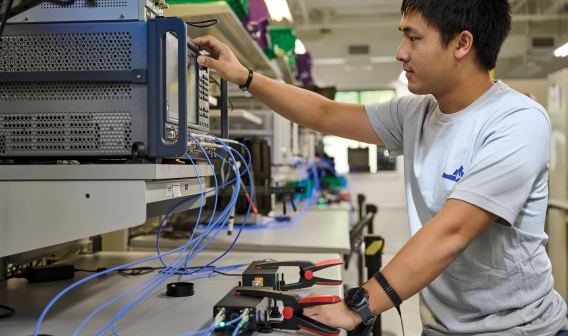

Advanced training opportunities abound in the region. Among other resources, the Crossroads Institute, established in 2005 in Galax, provides training and technology support to businesses. The institute combines services from Wytheville Community College and other regional partners to provide the state-of-the-art technology needed to support advanced manufacturing businesses as they grow. Its small business development center provides one-on-one support in business plan preparation, and its higher education center offers workshops and degree programs. Located close to its main production facility, Moog Components Group — Galax has been a tenant of the institute since 2012. The company manufactures printed circuit boards and has used the Crossroads center to help train its current and future workforce. It’s a process that demands intense training and attention to detail.

Moog — Galax’s niche is in developing prototype fast-turnaround, low-volume production circuit boards. Custom products might feature 24 intricate layers of materials that still come in at less than half an inch thick, all built to commercial or military standards which meet modern high-speed technology requirements. The company notes that it constantly invests in new equipment for this facility to ensure it maintains its competitive advantage. That means there is constant need to train technicians on the use of the latest vacuum press laser routing technology or circuit testing instruments.

Advanced materials companies like Moog, General Dynamics, Amcor Rigid Plastics, and Strongwell are continually giving back, developing their own workforce but also supporting education and training initiatives throughout the region. The same can be said of Scholle IPN, the Southwest Virginia Alliance for Manufacturing’s two-time (2017 and 2018) Manufacturer of the Year. The Illinois-based company manufactures flexible packaging solutions for the food and beverage, agriculture, automotive, cleaning, personal care, and pharmaceutical sectors at its 100,000-square-foot plant in Chilhowie. In presenting the award, the Alliance cited the way the company engages employees in process improvements. The company’s unique program recognizes employee contributions that boost plant productivity. It’s a win-win for management and the employees who are challenged to contribute more to their jobs, making work more productive and engaging. And the success is tangible. In March, the company announced it will invest $10.29 million and add 42 new jobs to expand its production facility.

Upon announcement of the project, Kent Kisselle, vice president and general manager of Scholle IPN’s North America region, stated, “Southwest Virginia is a strong fit in terms of high-quality labor availability and runway for additional investment, led by a solid leadership group ready to execute our strategic initiatives.”

While manufacturers often are thought to favor larger metro areas to have ready access to skilled workers, the company’s decision to expand operations in Smyth County suggests that a dedicated workforce and industry-leading training programs can offset apparent size advantages of bigger markets.